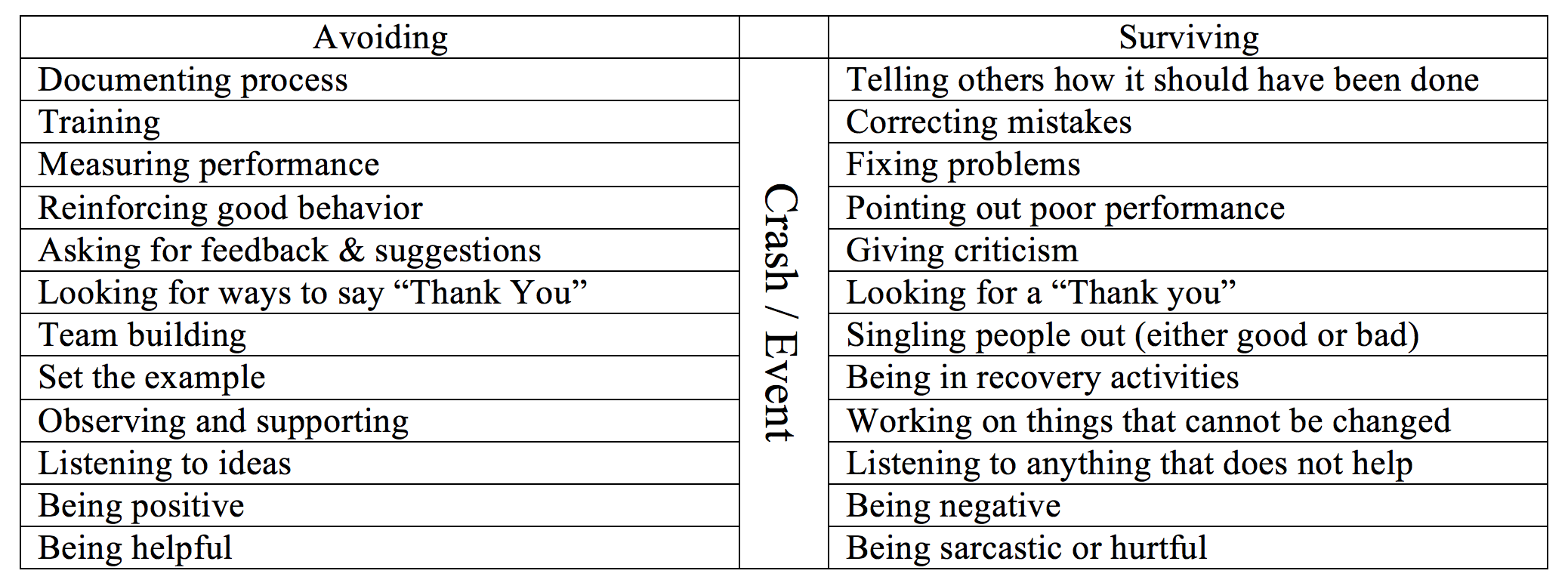

Boarding a Plane I was in the Nashville airport recently traveling home from a dealer visit. The dealership I was at is very good and continually getting better. An issue I have been helping them with is getting ahead of issues. When there is an issue they are experts at making things right. Few are better at making an unhappy customer happy again. Research tells us that customers who had an issue resolved to their satisfaction are more loyal than customers who never had an issue in the first place. The problem is, it extracts a huge toll on time and resources. Plus, we never know how many customers were unhappy and never let us know. The related tension creates a culture focused on issues rather than successes and can be tough on employees. Being in the airport reminded me of a recent article I read in Automotive News about how differently the auto industry and the airline industry think about safety. The auto industry has focused on crash survival for a century and have done an amazing job. Automobiles are vastly safer than they have ever been. Even though there are more accidents, significantly fewer people are injured or killed than ever. This is very good but consider this. Nearly all the technology, time and money is focused on what happens after the crash. There is a direct correlation to a typical managers’ day inside most dealerships. When thinking of safety, the airline industry begins from a completely different starting point and mindset. Since no one normally survives an extreme and rapid loss of altitude or survives a 500-mph sudden stop, they spend the clear majority of their time and resources focused on crash avoidance. Because they think differently, they behave differently. So, what? Well, look at the difference between avoiding and surviving as it applies to my friends’ dealership. I think one of the clear differences is that when there is a crash at the dealership no one dies. In fact, no one may even know. The customer just goes away and we never hear from them again unless they are upset enough to take some of their time to post something nasty on the internet. Same with employees, they seldom fall over after being injured by a manager. They just decide to quietly look for another job and eventually leave. Crash Avoidance: The airline industry usually gets its pilots from the military. These are mostly young people who have dreamed of being a pilot, gone to college and spent thousands of hours conditioning their bodies and minds. They have been relentlessly tested and earn higher rank as they prove their proficiency. They don’t sit in the pilot seat until they prove themselves. Even then, they are with an instructor. Crash Survival: Managers are experts at apologizing, redoing and placating customers. Why? They are the only ones with the skill or authority. Nearly no-one grows up hoping to be a service advisor or car salesperson. We hire people with little or no training and put them in front of customers within a week of their arrival. They learn their trade on your customers with no skill path or internal certification. Because of this, front-line folks are seldom equipped or have the authority and budget to do whatever it takes to make a customer happy. Crash Avoidance: Whether a pilot, flight attendant or ground crew they use tools like the pre-flight checklist to ensure everything goes right. They don’t leave things to chance. They document it. They measure it. They drill constantly. They don’t vary from or change the established process. Everyone knows what it is and everyone can see if it is being followed. Crash Survival: Managers are experts at discovering what went wrong and pointing it out. Why? They are the only ones that know what should have happened. The processes are generally tribal folklore, stories passed down from one generation to the next. If the process is documented, few can find it or recite it. Process checklists and consistent process training are often non-existent. Process is used to assign blame for not following it in the wake of an issue. Crash Avoidance: The airline pilots, flight attendants, gate agents, ground crew relentlessly practice. They use simulators and learn how to handle even the rarest situations they may face before they must. They don’t wait to practice until a plane hits a flock of geese on takeoff over one of the most heavily populated places on earth. They are prepared and confident. Crash Survival: Managers are experts at “keeping people on their toes”. Why? They make sure their people are aware of their mistakes. They put employees in situations they have never dealt with before using equipment they are not familiar with and let them practice on their customers. Then they wait for the crash. When things go wrong the focus is on what their people did wrong instead of what their manager should have done. It is too late to reinforce the things employees do right. We teach them to prepare for the crash, not how to avoid it. Crash Avoidance: Everyone knows each other’s job and are empowered to say something. They work together. If anything goes wrong everyone is affected. Studies show that airlines with the highest incident rates are the ones where it is unacceptable for a subordinate to question a superior. Crash Survival: Managers are experts at taking control and looking like heroes. This is a huge red flag! The very fact that there is a situation points to the fact that they didn’t avoid it. To avoid a crash, you need to value everyone in the organization, their opinions and talents. Create a culture where people speaking up is welcome. You see, in a dealership no one dies. In a plane, everyone does. Start by tracking how many issues arise. The goal is to reduce the number. If you are not good at that you shouldn’t be asking to fly the plane! I was with a pilot who told me that none of the items on a preflight checklist were put there just because someone thought it was a good idea. They are there because something bad happened that we don’t want to happen again. He said, “Good judgement is the result of experience. Experience is the result of bad judgement”. An incident that results in no change in your routine is a sure sign that it will happen again. Look at how you and your leadership are using your time. Create a chart with two columns and track what you are doing every half hour for a month. You will begin to get a very clear picture. Here is the thing to remember as a store owner. You are paying for their time! How it is being used is the most important thing! Are your managers spending their time prior to or after events happen? Consider time spent preventing issues as extremely valuable. Consider time spent after the issue as worthless other than to clean up the carnage and settle the law suites. How good is your organization at avoiding crashes? You could point to your online reputation, customer satisfaction index or policy account, but I have a better idea. Far more of your customers arrive at your store for service than sales. Tomorrow, drive up to your service entrance. Shut off the engine. Close your eyes and take a deep breath. Imagine you are going on vacation with your family. Ask yourself, “If this place were an airport and the people inside were ground crew and pilots, would I board the plane”.

0 Comments

There are seven things you control that directly influence your Service bottom line.

1 Calendar Utilization 2 Daily Clock Hours 3 Number of Technicians 4 Proficiency 5 Effective Labor Rate 6 Gross Retention Rate 7 Expenses This installment deals with Proficiency. Why is it important? You have begun to measure “Utilization” of time. You have decided how many days you will be open, how many hours you will be open each day and how many technicians you will employ. If you have ever built a race engine, this is similar. There was a lot of anticipation. You took every detail into consideration, matched up the best available parts that compliment each other and learned the best techniques to put them all together. At some point you needed to move past the anticipation, start the engine and see how much horsepower it produced. Many an engine builder has been surprised (negatively or positively) at the output of their project. When Ron Stoner and Skip Vandervall wrote “The Seven Controllables of Service Department Profitability” they called this measurement “Productivity”. When I was a service manager it was the primary measure I was most interested in. In its simplest form it is the billable hours produced as a percent of clock hours available. i.e. 10 techs - 8 hour day - 100 hours billed - equals 125% productivity. What do you do if the productivity is low? You quickly learn that there are actually two very important elements that make up productivity. Thus, the heated discussions that always come up whenever it is mentioned. People are talking about three different things. Folks can’t even agree on what to call them. Some people came up with “Proficiency” as a way to explain the combination of the two key elements. Ron & Skip had it wrong. There are 8 controllables. They talked about, but left out technician efficiency. I have changed the forecast tool to utilize it. Let me explain. You will remember I drew an analogy between a combustion engine and a service shop. The combustion engine draws in air, mixes it with fuel. lights it up and converts the heat to motion. A service shop engine opens the doors, adds some techs, gives them what they need and converts time into money. Once a technician arrives, any time not spent working on a job is lost. You cannot recover it. I see this in shops where techs come in late because they have gotten used to advisors not having jobs ready to hand out when they arrive on time. It is especially evident in Marine where large amounts of time can be lost moving boats to and from the water or storage. I also see it at parts counters where nothing starts until a tech requests a part and discussions of weekend activities begin to add up into mountains of non-refundable hours. How effective an organization is at keeping technicians productive needs to be measured. It is the first important element and is what I now refer to when using the term, “Productivity”. In its simplest form it is the hours spent working on jobs as a percent of clock hours available to work on jobs. The second and missing element is technician “Efficiency” or how fast they complete jobs. In its simplest form it is the hours billed as a percent of hours spent working on jobs. So, what would high productivity look like? A technician arrives and has a job in their bay. He punches in the time clock, punches on that job and starts working. He doesn’t need to stop to obtain parts or find tools. When he is done there is another job waiting. What is efficiency? Once on a job he works smart and completes it quickly and accurately the first time. Previously, in the forecasting tool we would multiply the total clock hours available by “Proficiency” to determine how many billable hours the shop will produce. In the new version we multiply the total clock hours available by “Productivity” to determine how many of those hours the techs will spend working on jobs. Then, we multiply that by “Efficiency” to determine how many billable hours will be produced in that amount of time. i.e. Previously a store may have been open 24, 8 hour days a month with 6 technicians for a total of 1008 clock hours. We multiplied 1008 by 90% Proficiency and it equaled 907 billable hours. How do you improve it? Are the techs the issue or the organization? Now you will be able to apply the “Efficiency” metric as well as the “Productivity” metric and see how each individually impacts your bottom line. i.e. 1008 clock hours times 85% Productivity = 857 hours on jobs times 106% technician “Efficiency” = 907 billable hours. Next: Controllable #5 - Effective Labor Rate. There are seven things you control that directly influence your Service bottom line.

1 Calendar Utilization 2 Daily Clock Hours 3 Number of Technicians 4 Proficiency 5 Effective Labor Rate 6 Gross Retention Rate 7 Expenses This installment deals with Daily Clock Hours. Why is it important? Making decisions that effect the lives of your employees can be difficult and can cost you great people if you are not careful. The hours you are open need to align with the hours your customers are shopping and buying. In addition to those pressures, you need to make a profit or everyone could be out of work. Luckily, service departments are not normally servants to the same demands as sales departments. Unless you are competing in the Express / Quick service market customers are accustomed to “normal” work hours in exchange for expert work. There are choices that need to be made to capitalize on demand, especially in cyclical businesses like marine or power sports. In the busy season do you extend hours, hire more people, both? Where do you find a qualified person? In the “off” season will you be able to afford to keep them? Can you find one that will work part of the year? Maybe you can do something creative to provide for demand without overworking your people, like installing a four-10-hour day schedule. In a team of 5 technicians, going from 40 hours in 5 days to 40 hours in 4 days lengthens your day by 2 hours and allows room for an additional technician where work bays are at a premium. These are all questions you may be considering. It is good to know how they will impact your bottom line ahead of time. As an example, plug these numbers into the “Forecast” tab of the Numbers Worksheet to experiment with your choices. Let’s take a look at a service department that is open 8 hours, 24 days in a given month with 5 technicians. This hypothetical store is netting $10,669 currently. Without changing anything else, adding a technician will take their net to $19,202. If this employee is full time, about 25% of their pay needs to be added to the expenses. Paid $20 an hour that would be about $40 a day or $3,840 a month in additional expense. Their net will now be $15,362. How about if they just extend their work day by 1 hour without hiring another tech? Assuming there would be little or no additional expense their net would go to $16,002. How about if they had 2 technicians come in for a half day each Saturday? That would add another $1,422 to the bottom line before subtracting any additional semi-fixed expense they might incur. When adding additional hours don’t assume that the choices you make will provide the same net result. Next: Controllable #4 - Proficiency. Now that you have considered how many work days are available and how many clock hours you may be able to extract from those days, my next post we will look at two things you control that determine how much of that time you will actually bill a customer for. There are seven things you control that directly influence your Service bottom line.

Why is it important? Especially in a cyclical business like the boat or power sports industry, it is important because you need to be able to make decisions about hiring, scheduling and shifting optional days off to match your varying work load. I was recently talking with a store owner who told me that at the end of their busy season her service manager used valuable technician time to do extensive work on a boat they had already brought in for winter storage and would have on site for months. Customers who only needed a small repair to keep boating were put off (lost business). Customers who already had their boats scheduled were delayed (lost trust and loyalty). Work needed to keep techs productive in the winter was no longer available (lost revenue). Consistently having technicians available to match customer demand is the foundation you need to make money and loyal advocates. This year there are 22 weekdays in December. Because Christmas day is on a Sunday, you could theoretically work all 22 days. 22 days x 6 technicians = 132 work days. If they all show up for work every one of those days your calendar utilization would will be 100%. You may decide to give everyone Friday off to spend at home getting ready for Christmas morning. They will work 126 days and your calendar utilization is now 95%. You may be slow between the Holidays and your are considering letting 2 technicians take off the entire week between Christmas & New Years to be with their families that live far away. Your team will work 116 days or 88% utilization. Plug these numbers into the “Forecast” tab of the Numbers Worksheet and you will see that the difference in NET profit between 100% utilization and 88% is about $7000. Anticipating this before your month begins lays the groundwork you need to make other decisions that impact your profitability. When tracking it in the “Daily Input” tab start by identifying the available work days in the top row for each technician. Each day when you insert the number of jobs they work on the spreadsheet will calculate your calendar utilization in the “Daily Performance” tab. Next: Controllable #2 - Daily Clock Hours. I run into Service managers who are very good at what they do and work very hard every day to increase their volume or profit. Most are working on pricing and strategy. Many are looking at every repair order attempting to find hidden money and ways to handle each transaction that will generate or retain a few more dollars. Nearly all look at their schedules and attempt to have the right techs on hand for the work coming in.

You have heard me say this before. In Service, the only thing you have to sell is time! I had the opportunity to work with a very talented man who created Express Service for a few major auto manufacturers. One of those manufacturers guaranteed “29 minutes or the next one is free” in all of their promotional materials. One thing he would drill into everyones head was that “Steps and Seconds Matter!” Fast forward, I was with a store owner who said he would be content if his service department turned vehicles in 45 minutes. I told him he would not be able to market a 45 minute oil change when there were 50 other places in his town that were advertising Jiffy/Express/Quick at 30 minutes or less. The bigger issue was the lost revenue. To illustrate how much money we were talking about I asked him what a minute was worth. It certainly doesn’t seem like much. “Just a minute”. We hear it all the time. When we talked about this his service department was averaging 38 minutes from the time a Customer was greeted till they were paying their bill and they wrote 1019 Quick repair orders! A minute saved on each of those would amount to 17 hours! I consistently trained teams that could easily do a vehicle inspection, oil change, tire rotation, replacement of wipers and an air filter in well below 20 minutes. I knew they could get to 28 minutes. If they did, they would gain 10 minutes per transaction or 170 hours per month. Enough to do another 364 Quick RO’s, a 36% increase in volume and a huge gain in net profit. You say, you don’t have Quick or Express service. It is even more important for your main shop! The transactions are far more complex there. (Go to the advisor - get a job - go to the clock and punch on the job - find the keys - find the vehicle/boat/RV/motorcycle - test for the concern - diagnose primary concern - do a complete multipoint check - get part prices - present findings to advisor - advisor presents to customer - wait for approval - get parts - break out tools - do the repairs and maintenance - ensure the repair worked - QC - clean up - park the vehicle - place the keys - punch out - take the RO to the advisor - put away the tools - get the next job, etc, etc.) You can’t tell me that if you brought everyone together, asked “How can we save just one minute?” that they couldn’t reduce that time dramatically. This store wrote 1223 main shop repair orders that month. If they could save just .2 hr (12 minutes) per RO that would be another 245 hours x their productivity x their effective labor rate + their parts to labor ratio which would have ended up being another $600,000 dollars! What to do? Start by looking at your Service process, from the time a customer arrives till they leave. You don’t need to define it all and drive yourself nuts with paperwork. Buy a stopwatch and use it! For at least 3 transactions each week, just time each step: the reception, the write-up, the movement of the vehicle, complete diagnose and inspection, get approval, and so on. Share the results with everyone involved. Make a scoreboard that everyone can see and update it every week. Let them come up with the ways to reduce the time. I worked with a store that was doing some great things to try and improve their profitability. They examined how well they worked together as a team and began to support each other better. They redesigned many or their processes to be more streamlined. They checked pricing of their most frequently asked for items in their market and made adjustments. They even changed the facility to make it more comfortable for those who were waiting and shopping. I was reviewing customer satisfaction survey results with the store owner prior to meeting with the rest of his management team. It became obvious to me that I missed something important when coaching them.

We could see some very good things happening. Overall, the customer experience was good. There were no complaints about prices, very few about time, only one about quality of work. But, there were a few items that clearly needed improvement. Two glaring deficiencies for his service department were “Advising of Additional Concerns” and “Review Inspection/Check-up Report”. These are 2 things that differentiate order takers from service providers. Both paint a clear picture of the low level of communication they engage in with their Customers and their level of concern for their customers current and future needs. Were long-lasting relationships with the people who ultimately pay for everything even important? The only time the store owner got animated was when he was describing how they coached the advisor to present and ask for the survey. His eyes lit up as he viewed his imaginary vision of a perfect plead for excellent! I attempted to bring him back to the behaviors displayed on the report a few times. I finally asked this question, “Doesn’t it concern you that your advisors are talking to your Customers about the survey instead of what they need or when they will see them next?” He was speechless at first, which scared me. “Have you made the desire for a perfect score more important than the service needs of the people who pay all your bills and keep your doors open! Shouldn’t you be coaching them on those behaviors instead?” The point is, you can’t buy anything with a survey. A great book that illustrates this is ‘Customer Satisfaction is Worthless, Customer Loyalty is Priceless’ by Jeffrey Gitomer. We talked about the impact these behaviors were having on his profitability. Following is what he concluded. Any additional items recommended and purchased would increase revenue directly. It would also make the shop more efficient. They would be able to process fewer vehicles to earn the same amount of money. It would increase capacity. They would spend more time working on vehicles and less time moving them. The parts department would realize an immediate windfall without any additional expense. Their expenses would decrease significantly. Loyal customers return twice as often and refer others 3 times as often as merely satisfied ones. Engaging them in a conversation about what is important to them now and what they will need next would fill their shop. It would also buffer them against market fluctuations and decrease their advertising budget. Most importantly, their customers would feel that their wants and needs were more important than a perfectly worthless survey. So, here is my suggestion to increase your bottom line without spending a penny to do it. Schedule time to regularly and frequently observe the conversations your people have with your service customers from your customers point of view. Record and listen to phone calls together. Rate these conversations on a point scale and post them if you want everyone engaged. If you are not sure how to completely satisfy your customers listen for and make sure you do those things that make them say “Thank you”. They thank you for listening to them, showing that you care, building rapport, addressing their concerns, keeping your promises and keeping them from having issues in the future. I would be willing to bet you will never hear a customer thank you for instructing them on how to take a survey.  The Bible talks about how the rest of body follows the tongue. At a Leadership team meeting a few months ago the managers of a car dealership were talking about how difficult change can be. The team member survey results for one manager indicated many problems that pointed to his behavior as seen by the employees. Although everyone agreed he was a good person at heart, and he wanted to change, the task seemed monumental and he did not know where to start. I stepped over to a flip chart and said, “Start with something easy.” Before you say anything ask yourself, “Is what I am about to say focused in the past or future?” I wrote Past to the left and Future to the right and drew a horizontal line down the center. I facilitated a discussion. I then asked, “Is it Negative or Positive?” I wrote Negative at the bottom and Positive at the top and drew another line between them to form what looked like a crosshair. I facilitated another discussion. Then, I moved the discussion to where they were today and where they wanted to be tomorrow. I wrote Inspiring Leader in the top right quadrant, It was a simple exercise and they got it. When I was there recently their employee action team expressed how much easier it is to deal with him today. This simple technique changed him, the way he is perceived by others, their work environment and their culture. Watch your Thoughts for they become Words Watch you Words for they become Actions Watch your Actions for they become Habits Watch your Habits for they become your Character Watch your Character for it becomes your Destiny Margaret Thatcher “Simple, but not Easy” a friend of mine would say.

Start by forgetting most of what you already know about technician skill levels, pay and schedules. The market has changed. Like it or not, cars are far more complex, but break less often. If your shop is dependent on warranty or heavy repairs you are at the mercy of a declining market. 20 years ago a typical dealership service department could ignore the light services and did because 50% to 75% of the revenue came from warranty. We created a whole industry of Jiffy, Express or Quick service outlets. Most of the rest of our revenue came from repair work that was out of warranty. Warranty now represents about 15% and if customer pay repair work is the majority of your revenue, you are probably still ignoring the light services and customer loyalty that go with them. It is a sign that you are short on capacity and should be looking to grow. You ask how? Even if you have the bays, you can’t find the technicians. We’ll get to that. To make matters worse, our education system has clearly abandon the trades and left them begging for talent. All the trades are competing for qualified workers. While you are looking for technicians, every other company that needs someone to perform a task with their hands that doesn’t involve sitting at a desk are searching, too. Those that are available are not trained. The only way you can get a qualified main shop mechanic is to BUY one at a higher rate than anyone else in your area is willing to pay. Or, hope that their spouse gets a great job in your vicinity, they need to move from wherever they are now and happen to stumble into your store. Great talent exists, but you won’t find it if you are looking for someone who has automotive training, a chest full of expensive tools and grease under their nails. They may be looking for a career, but not sure what career or fully committed or able to work “full-time” yet. Here is a career path that works well:

The next step:

I get the word of the day from Webster’s dictionary and today I received one that I am very familiar with and we all use often in the car business. The truth is, the ability to build rapport with customers is essential for sales and those that cannot don’t make it.

Because it is familiar, I almost trashed the email before I read the definition. When I did, the question that popped into my mind that you may want to ask yourself as a leader in your store is, “Do I expect and create relations marked by harmony, conformity, accord, or affinity (rapport) between my employees and myself? The truth is the same for leadership as it is for sales. The ability to build rapport within your team is essential and those that cannot don’t make it. |

Ed AlosiThoughtful observer of actions and results in the Retail environment. Archives

February 2022

Categories |

RSS Feed

RSS Feed